Contact Us

Contact Us

Contact Us

Contact Us

One of the continually evolving technologies in the construction sector is the 3D concrete printer. 3D concrete printers are innovative technologies that enable construction projects to be executed faster, more efficiently, and cost-effectively. In this article, we will delve into what a 3D concrete printer is, how it works, its advantages, and its effects on the construction industry.

A 3D concrete printer, as the name suggests, is a device that utilizes 3D printing technology to produce components or certain structural elements of buildings. This technology has been developed as an alternative to traditional construction methods.

A 3D concrete printer takes a digital model created using computer-aided design (CAD) software.

The software determines how the concrete will be layered, and it transfers this information to the 3D concrete printer.

The printer deposits layers of liquid concrete or concrete mix, and when one layer is complete, it moves on to the next layer.

This process is repeated until the final structural element is completed.

3D concrete printers offer several advantages:

1. Speed and Efficiency: Compared to traditional construction methods, 3D concrete printers work much faster. The layer-by-layer construction of the building reduces labor time and costs while significantly shortening the project completion time.

2. Cost Savings: Due to reduced labor and time costs, 3D concrete printers lower construction expenses. Additionally, by minimizing waste and using materials efficiently, project budgets can be managed more effectively.

3. Design Freedom: 3D concrete printers can easily construct even complex geometries. This allows architects and engineers to design more creative and aesthetically striking structures using their imagination.

4. Sustainability: While concrete is one of the most widely used construction materials, traditional construction methods often result in wastage. 3D concrete printers promote sustainable construction practices by optimizing material use.

5. Reduced Labor Requirements: Compared to traditional construction methods, 3D concrete printers require less labor. This reduces the dependence on human labor for projects and enhances job safety.

Challenges

1. Material Quality: The durability and other physical properties of the concrete mix used in 3D printing are crucial, and sourcing high-quality materials can be challenging.

2. Regulations and Standards: Using 3D concrete printing technology in the construction industry might require updating certain building standards and regulations.

3D concrete printing technology emerged from the integration of digital design and automation into the construction sector. This technology is a combination of software and hardware that controls construction processes through digital data. The pre-designed digital model sends instructions to the concrete printer and coordinates the actions.

The use of 3D concrete printers is rapidly growing worldwide. These printers are utilized in various construction projects, including residential houses, office buildings, bridges, and industrial facilities.

In emergency situations that prioritize sustainability and rapid construction, such as earthquake-damaged areas, the use of 3D concrete printers is increasing. These printers allow for more effective reconstruction of damaged structures.

3D concrete printing technology has several positive effects on the construction industry:

1. Rapid and Efficient Construction: 3D concrete printers enable faster building construction compared to traditional methods. This shortens project timelines and saves time.

2. Reduced Waste and Costs: 3D concrete printers minimize material waste due to optimized usage, leading to cost reduction. This technology is an economical construction method due to reduced labor costs and efficient material usage.

3. Design Freedom and Flexibility: 3D concrete printers allow architects to bring imaginative designs to life. Complex and unique designs that were previously difficult to achieve with traditional methods can be easily constructed.

4. Sustainability and Eco-Friendly Approach: 3D concrete printers promote sustainable construction by minimizing resource consumption and waste generation. They also provide opportunities for energy-efficient and environmentally friendly buildings.

3D concrete printers are considered essential technologies for the future of the construction industry. Continuously evolving and improving, this technology has the potential to revolutionize the construction sector.

In the future, structures built using 3D concrete printers are expected to become more widespread. Particularly, the rapid construction of large and complex structures will further highlight the value of 3D concrete printers. Additionally, the development of innovative materials and concrete mixtures will enable the construction of more durable and environmentally friendly structures.

Architects are expected to create even more aesthetically pleasing and unique designs with the flexibility offered by 3D concrete printing. Moreover, the integration of 3D concrete printers with robotic systems and artificial intelligence will play a significant role in automation and increased efficiency in construction processes.

3D concrete printers come in various models with different specifications and features. These printers vary based on the size and complexity of the structures to be constructed, as well as the materials to be used.

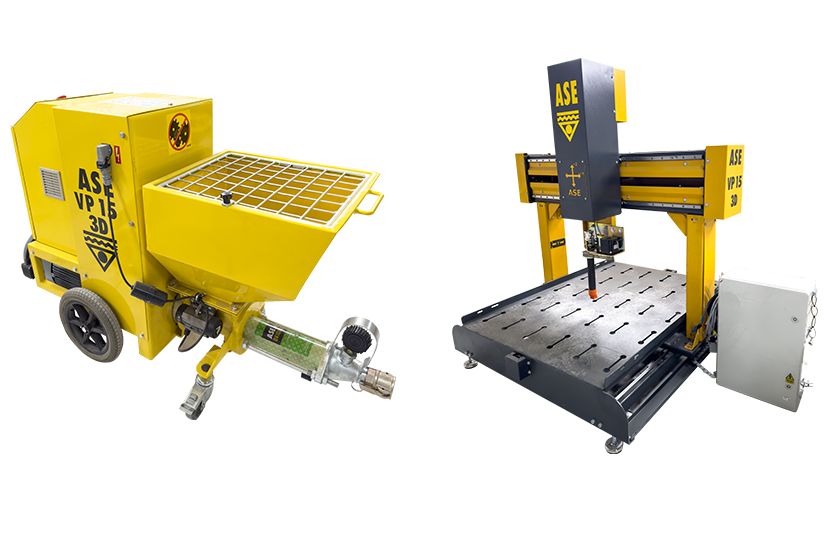

1. Portable 3D Concrete Printers: Ideal for small-scale projects, portable 3D concrete printers are cost-effective and easily transportable. They are used for projects with space constraints or in emergency situations.

2. Industrial 3D Concrete Printers: Designed for large and complex projects, industrial 3D concrete printers have high capacity and automated processes. They enable the rapid construction of large structures.

3. On-Site 3D Concrete Printers: On-site 3D concrete printers allow for the direct production of structures at the construction site. These printers save time and money by constructing structures where they are needed.

Concrete 3D printing technology has a wide range of applications beyond residential homes:

Road and Bridge Construction: Cement 3D printing can be used in road and bridge construction to facilitate the rapid construction of durable and long-lasting structures. This technology is especially suitable for producing specialized structures such as bridge railings and infrastructure components.

2. Industrial Facilities: Cement 3D printing technology can also be used in the construction of factories and industrial facilities. It offers cost and time advantages in the construction of facilities with specific requirements.

What are the advantages of a 3D concrete printer?

The advantages of a 3D concrete printer include:

- Speed and Efficiency: 3D concrete printers enable faster building construction, leading to shorter project timelines.

- Cost Savings:

Due to reduced labor and material costs, 3D concrete printers lower construction expenses.

- Design Freedom: 3D concrete printers allow for the construction of complex and creative designs.

- Sustainability: 3D concrete printing minimizes material waste and promotes sustainable construction practices.

What materials does a 3D concrete printer use?

3D concrete printers primarily use concrete, the most commonly used construction material. However, the concrete mix can be customized based on the printer's specifications and project requirements. Specially designed concrete mixes are used to enhance flowability and layer durability.

What is the cost of 3D concrete printing in construction?

The cost of 3D concrete printing technology varies based on project size, printer features, and material usage. Generally, the cost of 3D concrete printing is lower compared to traditional construction methods due to reduced labor and material expenses.

What size of structures can be constructed with a 3D concrete printer?

The size of structures that can be constructed with a 3D concrete printer depends on the printer's capacity and technical specifications. Industrial 3D concrete printers can construct large-scale structures, while portable models are suitable for smaller projects. However, 3D concrete printers can be used to construct structures of varying sizes.

What are the advantages of 3D concrete printing over traditional construction methods?

Advantages of 3D concrete printing over traditional construction methods include:

- Rapid Construction: 3D concrete printing technology allows for faster building construction through layer-by-layer processes.

- Reduced Waste: 3D concrete printing minimizes material waste, leading to more efficient material usage.

- Design Freedom: Complex and unique designs can be easily realized using 3D concrete printing.

- Versatility: 3D concrete printing is not limited to residential homes; it can be used in various construction fields.

Is cement 3D printing only for residential homes?

No, cement 3D printing technology can be used for a wide range of applications beyond residential homes. It is applicable in various fields, including industrial facilities, bridges, and architectural elements. This technology offers versatile solutions for many different areas of the construction sector.